MACHINERIES

home > machineries >

xlpe insulation

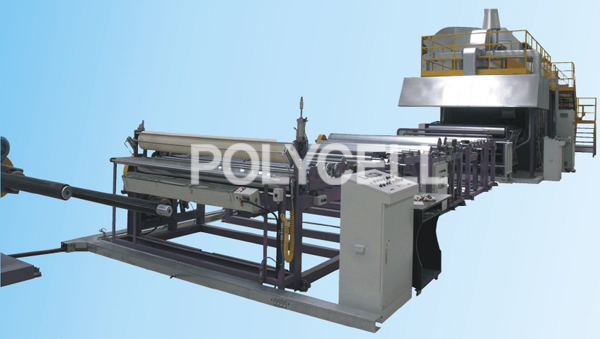

CHEMICAL CROSS-LINKED PE FOAM PLANT

Chemical Cross-Linked Polyethylene Foam Plant consists of Compounding part, Extruding part, Cross-Linking part and Winding part as final. This line is manufactured by using the most advanced and innovative technologies. The chemically Cross-Linked PE foam sheet is produced by roll type and is widely used in the field of construction, industrial, automobile, sports & leisure and so on. The products are available in roll or sheet form, with a consistently smooth surface, in a wide range of controlled thicknesses (from as low as 3mm up to 50mm laminates).

specification

| ITEM/MODEL | PKC-150C | PKC-150C |

|---|---|---|

| CAPACITY | 100~170kgs/hr | 350 kgs/hr |

| AVAILABLE WIDTH | 800-2000mm | 800-2000mm |

| AVAILABLE THICKNESS | 3-20mm | 3-20mm |

| DENSITY | 25-200kgs/CBM | 25-200kgs/CBM |

| ELECTRICITY | 600kw | 600kw |

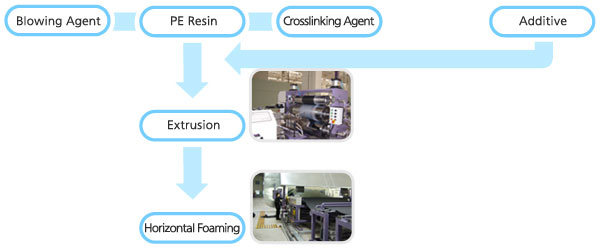

MANUFACTURING PROCESS

1. COMPOUNDING PART

(Kneader)

(Kneader) (Pelletizer)

(Pelletizer) (Drum Dryer)

(Drum Dryer)

2. MOTHER SHEET EXTRUDER PART

(Extruder)

(Extruder) (T-Die&Polishing Roller)

(T-Die&Polishing Roller) (Cooling&Expanding)

(Cooling&Expanding) (Winder)

(Winder)

3. CROSS-LINKING PART( FURNACE )

(Cooling Roller)

(Cooling Roller) (Foam Winder)

(Foam Winder)

PROPERTIES

- Fine, uniform, closed-cell structure, with a smooth skin on both surfaces

- Excellent mechanical properties at very low densities

- Excellent thermal insulation

- Temperature resistance from -80°C up to 120°C

- Very low water absorption and vapor transmission rate

- Excellent chemical resistance

- Good weathering resistance

- Excellent gauge (thickness) control

- Easy to convert

- Non-toxic and environmentally friendly

- Foams can be die-cut, water jet-cut, slit and thermoformed into simple or complex shapes.

APPLICATION

1. BUILDING & CONSTRUCTION

- Heat insulation dew condensation-proof material

- Freezing-proof material for road and rail

- Protection for water-proof layer

- Sealer

- Lining material for roof, wall and floor

2. INDUSTRIAL APPLICATION

- Heat insulation material for refrigerator , Air conditioner and bath tub.

- Various kinds of insulation tubes and Gaskets.

- Air conditioner.

3. PACKING & PACKAGING

- Protection cover for household electric appliance, lights, watches etc.

- Cushioning material for glasses, foods and corner padding

5. AUTOMOTIVE

- Head Liner

- Trunk Mat

- Wheel Cover

- Seat Side Trim

- Sun-visor

- Insulation material for air conditioner

- Instrument panel

- Roll Type Product Working Process